Clean energy technologies, including wind turbines, solar photovoltaic panels and batteries, are essential for Australia’s transition towards net zero. However, the renewable energy transition poses questions around recycling, waste management and decommissioning of large-scale renewable energy projects and household solar panels and batteries. The clean energy industry takes these issues very seriously and is constantly innovating to improve management of the resources used for clean energy technology and infrastructure. Recycling, decommissioning and clean energy

Can materials from large scale renewable energy projects be recycled?

Clean energy technology and infrastructure can be recycled and decommissioned to lower the environmental impact of the projects and present economic opportunities to reduce the consumption of critical materials. This can be done by recycling metals and other valuable resources or repairing and upgrading equipment to be utilised elsewhere.

What is decommissioning?

Decommissioning means wind turbines, site offices and any other infrastructure is removed from a site (1). Disturbed areas and foundation pads are then covered and revegetated if necessary, allowing land to return to its former use. Sometimes, components of a project continue to service a functional purpose and will remain in place, following agreement from the landowner – for example, access tracks and fencing.

Who is responsible for decommissioning clean energy infrastructure?

The project owner is responsible for decommissioning. Requirements for decommissioning projects, such as land rehabilitation, are set out in the landowner contracts and planning and environmental approvals of the specific project.

Is there a time limit on decommissioning clean energy infrastructure?

Project contracts and approvals generally contain clauses around the amount of time between end-of-life of the infrastructure and decommissioning, including the expectations around rehabilitating the land and project site. If a clean energy project is sold, the new owner will take on the requirements and responsibilities contained in contracts with landowners and in planning and environmental approvals.

What happens if an asset becomes stranded and the owner can’t afford to decommission it?

The risk of assets becoming stranded for clean energy projects is low since the resource (e.g. wind, sun) will continue to be available and is likely worth continued investment. Clean energy projects in this way are different to mining. In mining, a resource can be depleted, meaning the site has less value.

When does a project owner put aside finances for decommissioning?

The required finance for decommissioning can be generated in just a few years of operation, so in most cases there is no need for financial assurance will take place around 3-5 years before end of life.

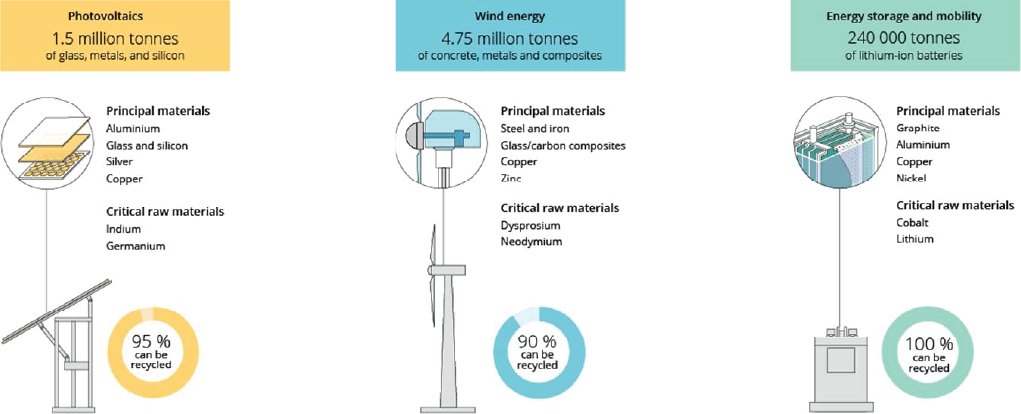

Does clean energy infrastructure use a lot of raw materials?

Deployment, maintenance and replacement of clean energy infrastructure requires significant resources, including critical raw materials. As clean energy infrastructure is being built, the industry can prevent future loss of valuable resources to landfill by ensuring materials are recycled for future infrastructure and technology needs.

Can recycled materials be used in the manufacturing of clean energy technology?

By using recycled materials, we can reduce the use of raw materials in new energy-generating products and in other manufacturing sectors. Global competition for materials essential to the renewable energy transition is projected to increase in coming years. Use of recovered and recycled materials, including critical minerals that can be extracted from end-of-life renewables and electronics, can help meet these demands.

Solar

What is the lifespan of a solar panel?

Large-scale photovoltaic (PV) solar panels generally have a lifespan of 25 to 30 years and will naturally degrade or lose efficiency over time.

Are solar panels recyclable?

Photovoltaic solar panels consist of 95% recyclable materials, including aluminium, glass, silicon, silver, copper, indium and germanium.

What parts of a solar panel can be recycled?

Up to 17 per cent of a solar panel, by weight, can be recycled in Australia. The panel’s aluminium frame and junction/terminal box, which houses the electrical connections, are the most common components to be recycled (2).

How much solar panel waste will need recycling locally?

The cumulative volume of end-of-life solar panels in Australia is expected to reach 1 million tonnes by 2035 and the total material value from end-of-life solar panels is projected to surpass $1 billion.

Wind

What are the environmental benefits of recycling PV solar panels?

The environmental benefits of recycling PV panels include the avoidance of global warming potential, ecotoxicity impacts and savings on water and energy (3). PV recycling can avoid the emission of up to 1.2 tonnes of carbon dioxide equivalent emissions for every tonne recycled (4).

What are the financial benefits of recycling PV solar panels?

Australia is potentially set to dispose of 34.6 GW worth of fully serviceable solar panels by 2045, which is the equivalent of all the solar panels installed in Australia today (August 2024). That provides an estimated economic value of $167 billion. Reusing these panels for continued renewable energy production could increase Australia’s installed capacity by up to 17 per cent by 2035.

Wind

What is the lifespan of a wind farm?

Approximately 20 to 30 years. Once it reaches the end of its operational life, there are several options to consider. These include extending the lifetime of the asset, partial or full repowering (i.e. replacing old blades, turbines or towers with new ones) and decommissioning.

.png)

Wind

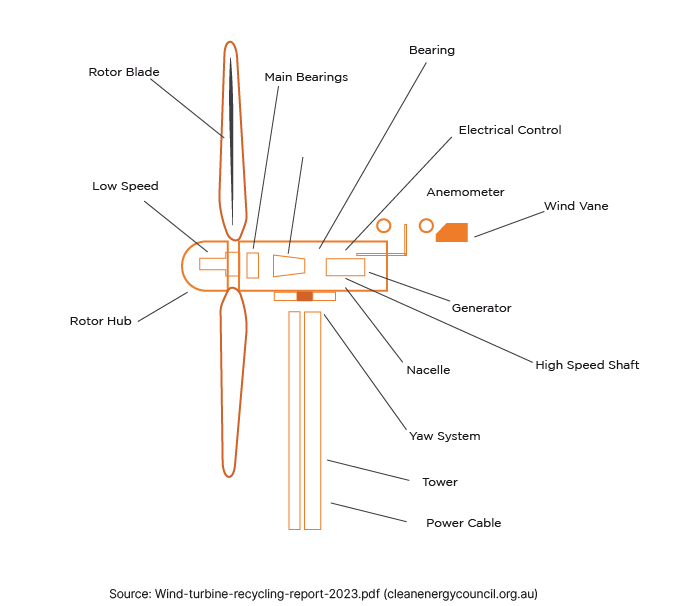

Are wind turbines recyclable?

Approximately 85% to 94% of a wind turbine (by mass) is recyclable and can be recycled in Australia. This recovery rate exceeds the National Waste Policy Action Plan target of 80 per cent average resource recovery rate from all waste streams by 2030.

.png)

1 Decommissioning: https://www.cleanenergycouncil.org.au/advocacy-initiatives/community-engagement/decommissioning#: ~:text=Decommissioning%20means%20that%20the%20wind,returned%20to%20its%20former%20use.

2 Solar recycling: Solar Panel Recycling in Australia | Canstar Blu

3 PV recycling benefits: High yield, low cost, environmentally friendly process to recycle silicon solar panels: Technical, economic and environmental feasibility assessment - ScienceDirect

4 PV recycling benefits: High yield, low cost, environmentally friendly process to recycle silicon solar panels: Technical, economic and environmental feasibility assessment - ScienceDirect

Can wind turbine blades be recycled?

Wind turbine blades are made of materials such as fibreglass or carbon fibre, as they are designed to be lightweight but highly durable. Composite materials are currently difficult to recycle, however wind turbine manufacturers are developing new blades that can be recycled as part of their commitment to zero-waste turbines by 2040 (5).

Are wind turbine blades repurposed?

Wind turbine blades can be repurposed for several alternative functions. In Europe, blades have been transformed into bus stops, playground equipment and public seating. Designs for structures such as bridges, poles and farming equipment to be made from repurposed blades have also been developed.

What is the process of decommissioning a wind farm? Decommissioning involves several different processes, including dismantling wind turbines and other above-ground infrastructure, removing them from site and rehabilitating the land, or in some cases, building a new wind farm on the same site.

What does the decommissioning of a wind farm mean for the landowner?

The Australian wind farm industry takes decommissioning very seriously. No wind farm owner has ever abandoned a wind farm in Australia.

Battery

What are lithium-ion batteries?

Lithium-ion batteries are the predominant commercial form of rechargeable batteries, commonly used in consumer electronic electronics and electric transportation, including electric vehicles (EVs). Most plug-in hybrids and all EVs use lithium-ion batteries.

Can lithium-ion batteries be recycled?

Lithium-ion batteries are a source of many valuable materials. If recycled, potentially 95 per cent of battery components can be recovered for alternative use or may even be turned into new batteries.

Are batteries made of critical minerals?

Critical minerals are essential for manufacturing batteries, electric vehicles, solar panels and wind turbines. The demand for critical minerals for batteries is expected to grow rapidly by 2030, with manganese, lithium, graphite and nickel increasing at least sixfold, and cobalt more than tripling.

Battery

What are critical minerals?

Critical minerals are metallic or non-metallic elements found in the earth that are crucial for modern technologies, economies and national security.

Is there a high demand for critical minerals?

The increasing demand for EVs and the rising number of solar and wind power projects means the use of batteries is expanding across the energy sector. It also presents challenges, as there is greater demand for critical minerals, battery recycling and the repurposing of facilities.

Is there a large amount of lithium-ion battery waste?

Lithium-ion battery waste is growing by 20 per cent annually and could exceed 136,000 tonnes by 20367.

Top 5 clean energy facts

The clean energy transition will create

66,000 jobs by 2030

As a windswept and sun-drenched land

Australia has an abundance of cheap and reliable renewable energy

Clean energy projects will deliver between

$7.7 billion - 9.7 billion in direct payments to farmers and nearly $2 billion to regional communities land councils by 2050

Clean energy is already supplying more than

40% of Australia’s electricity

Australia is already feeling the effects of a changing climate, with more intense heatwaves, droughts, floods, fires, ocean acidification and rising sea levels.

Clean energy is the best way to reduce emissions and prevent the worst impacts of climate change